Oxycom

Oxycom‘Natural cooling systems’ developed by Oxycom are based on the reliable, time-tested method of evaporative cooling and are remarkably efficient in the UAE climate.

1. IntrCooll : Provides natural and cool air to spaces (including open/semi-open spaces) to create a comfortable and healthy environment using innovative two-stage adiabatic cooling.

2. PreCooll: Increases the efficiency and life of existing cooling system using adiabatic cooling.

Cooling Solutions

Cooling SolutionsIntrCooll – REPLACE CONVENTIONAL AC

Innovative two-stage indirect / direct adiabatic cooling technology using only 10% of the energy used by traditional AC systems, IntrCooll® machines can effortlessly deliver cool air streams.

IntrCooll utilizes filtered, fresh outdoor air to cool. It continuously ventilates and changes the air multiple times every hour improving the comfort and health of the occupants in the area.

In large buildings, open areas, and semi-open spaces, IntrCooll® is the first and only environmentally friendly method for establishing and preserving a pleasant climate.

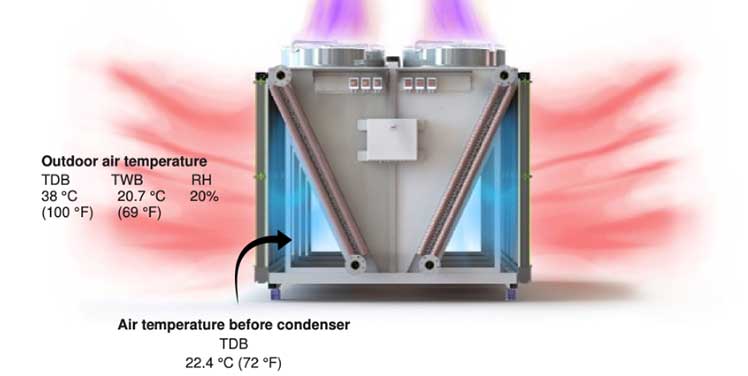

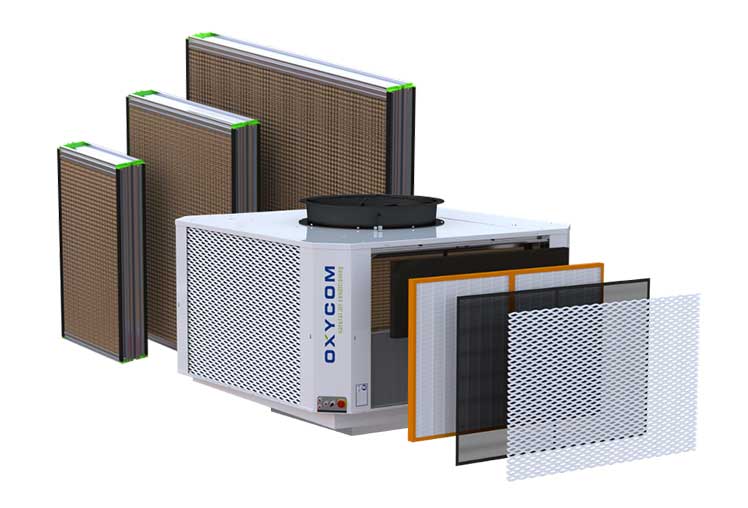

PreCooll – SUSTAIN EXISTING CHILLERS

A cool microclimate is created around your cooling system by patented PreCooll Oxyvap® panels. The inlet air temperature can be cooled by evaporative cooling up to 25°C. Deep cooling is achieved even on the hottest days due to PreCooll significantly increasing the cooling capacity of the existing chiller units.

Lowering the load and increasing the capacity can save up to a third on the running costs of your cooling system. In addition to improving efficiency, ensuring a consistent flow of cold air to your condenser also extends equipment lifetime and lowers maintenance expenses.

IntrCooll Technology

TWO STAGE ADIABATIC COOLING

Two-stage evaporative cooling, commonly referred to as indirect/direct cooling, cools the air using both indirect and direct cooling methods.

Cold recirculation water is used in the first indirect “cooling step” to pre-cool the ambient air in a heat exchanger. Because no moisture is added, the air that exits the heat exchanger has a lower dry bulb and wet bulb temperature than the ambient air. The air is further cooled by a second direct adiabatic “cooling step” using a wet evaporative medium.

Due to the two-step cooling process, the air may be cooled to much lower temperatures and can no longer hold significant amounts of humidity.

PreCooll Technology

DIRECT ADIABATIC COOLING

Since the water and the air stream are in direct contact, the process is called direct evaporative cooling, often referred to as direct adiabatic cooling or wet bulb cooling. Water is directly evaporated into the air stream during the direct evaporative cooling process.

As a pre-cooling method for commercial chillers, direct evaporative cooling is particularly efficient. This method of evaporative pre-cooling cools the incoming air before in an air-cooled chiller using a contact-humidifier (wet evaporative media). There will be significant energy savings as a result of the chiller’s efficiency being greatly increased.

Benefits

- Increased Comfort : Perfect temperature and humidity, year-round.

- Healthy Environment: Cool with 100% clean, fresh and, filtered outside air.

- Sustainable: Environmentally friendly alternative, with 90% lower energy consumption compared to conventional air conditioning.

- Increased Productivity: Productivity drops 2% for every degree above 22°C.

- Low operating & maintenance costs.

Benefits

- Energy Saving: Reduce your carbon footprint and save on energy consumption of the system

- No heat stress: PreCooll provides the assurance that chillers will not fail due to extreme heat.

- No corrosion: The aluminum fins are applied with an anti-corrosion, anti-bacterial, microbial, water absorption & distribution coating.

- Increase your cooling capacity: The incoming air is reduced up to 25 °C increasing the cooling capacity of your chillers.

Compared to direct adiabatic coolers:

- Up to 114% wet-bulb efficiency

- Up to 7°C lower temperatures

- Up to 70% less increase in humidity

- Up to 30% less water consumption

Upgrade your chillers by:

- Up to 40% energy savings

- Up to 20% more cooling capacity

- Up to 30% peak power reduction

- Up to 25°C pre-cooling

Oxycom's Customers

Awards

Certificates